You may not think much about the pavement beneath your feet, but a great deal of planning and preparation goes into the design, creation and laying of pavement. Pavement design in particular needs a lot of careful thought, as it is used in critical infrastructure projects such as the building of major highways, warehouses, large living and work complexes and transport hubs.

Because these areas see so much heavy traffic, finding out the best materials to make the pavement, the thickness it should be poured at, and any extra support under or beneath it that it may need are all critical to your project’s long-term success.

Geotechnical engineering plays a crucial role in the design of pavements in Melbourne, whether it’s a driveway or footpath, the road or the concrete of your workplace. Let’s discuss how vital it is and why companies that offer the services of geotechnical engineers are so important.

What exactly is geotechnical engineering? This branch of civic engineering involves testing and analysing the earth under our feet, including soil, rocks and any construction materials like crushed rock. Geotechnical engineers are used at the beginning of most projects, where the earth is used to build or support structures. They are also a prominent part of major road projects.

Geotechnical engineering is sometimes known as geotechnics. By solving engineering problems using the mechanics of rocks and soil, geotechnical engineering has become a vital component of many large-scale projects across the world. It often overlaps with geology, geophysics and hydrology.

By testing soil samples at potential construction sites, design engineers test for things like soil strength, soil density and groundwater conditions. Another important aspect is monitoring the behaviours of the soil, and the soil’s response to different pressures and movements.

With this information, professional engineers can then determine the best way to start the building project.

Do you need geotechnical engineering in Melbourne? SITE Geotechnical is an expert in everything geotechnical. Explore the range of geotechnical services we offer right here online.

Now that we know what geotechnical engineering is, how does it relate to pavement design in Melbourne? First things first, any pavement project will start with geotechnical engineers performing a pavement investigation or survey.

Here is what this kind of geotechnical investigation will involve:

Performing a geotechnical investigation can save larger projects millions of dollars. It’s always worth having an experienced engineer on your site, like one from SITE Geotechnical.

Here are some of the most important ways you can inform your pavement design with geotechnical engineering:

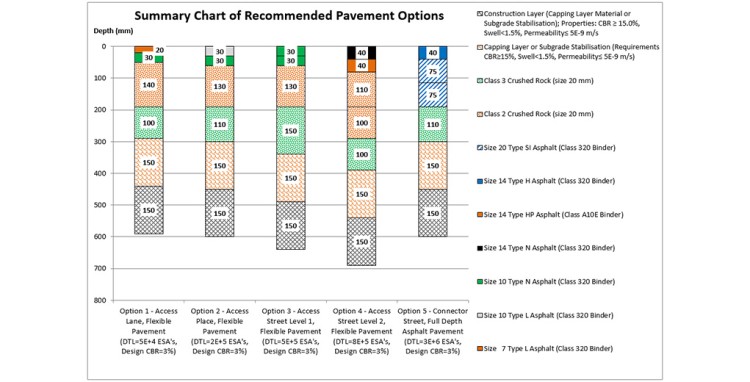

How thick should your pavement be? Generally you would think the thicker the pavement layer the stronger it will be, however by using materials like concrete, asphalt or stabilisation, a thin pavement can work. In many cases, it’s better to have options as there can be conflicting aims that will often need to be taken into account. By providing options, the client and contractors can balance any conflicting aims.

By testing the existing pavement materials and/or earth underneath your proposed project’s surface, you can determine the pavement composition requirements and ensure that your pavement will hold the expected traffic loadings without defects for decades. With appropriate pavement design, you can prevent the need for costly do-overs and fixes in the future.

This is especially important for industrial hardstand pavement, which has to withstand very heavy weights. This sort of pavement is seen in places like airports, warehouses and container yards.

SITE Geotechnical’s geotechnical engineers excel in innovative Pavement Design and can offer multiple options for your project.

How do you decide what type of pavement you will use? Asphalt or concrete are the main options, and each will play a crucial role in determining how long your pavement lasts. Each has its own physical properties, and geotechnical engineering can help you decide which one you will use in your construction project:

Through an in-depth geotechnical analysis, geotechnical engineers can provide options on which type of pavement is best for your project.

SITE Geotechnical offers many different types of asphalt and concrete for different projects. Here is just a sample of our options:

| Asphalt | Concrete | Other |

| Flexible asphalt surface pavements | Rigid reinforced concrete pavements | Flexible bituminous stone seal pavements |

| Deep-strength or Full-depth asphalt pavements | Concrete segmental pavements | Flexible unsealed pavements |

The experts at SITE Geotechnical use Pavement Computer Modelling (CIRCLY), a geotechnical design software, to assist with our pavement design process.

Your pavement is more than just, well, pavement. Sometimes, additional elements will need to be either used as a base or mixed into the pavement solution to give it more flexibility, structure or strength. By performing a ground investigation, geotechnical engineers will be able to determine if your pavement requires a little extra support.

Foam Bitumen Stabilisation (FBS) is a technique that adds bitumen to existing pavement material to enhance the strength of existing unbound materials and make them more like asphalt, making the original pavement stronger and more capable of withstanding higher loads. FBS is a great way to rehabilitate existing roads.

A geotechnical pavement investigation will be able to determine what your pavement will need to withstand the anticipated loadings and minimise future maintenance requirements.

Professionals like SITE Geotechnical will use the latest Publications And Design Tools to craft the perfect pavement plan.

Did you know your pavement can be made out of recycled materials and even existing materials within the road? By minimising the use of raw, natural resources, you can reduce your impact on the environment and save yourself some money at the same time. And choosing recycled materials doesn’t mean your pavement will be any less durable or strong. In fact, using recycled materials can actually boost the long-term performance of your pavement!

You can use recycled materials to stabilise pavement and prolong its lifespan, reducing your long-term costs, particularly for heavily used pavements. There are three types of materials used for recycled pavement, including:

A quality geotechnical analysis can help you decide if using recycled materials is a smart possibility for your construction project.

As you can see, having an expert who can perform Construction Professional Services (CPS) Design on your site can only benefit your project! Choosing reputable geotechnical engineers, like those from SITE Geotechnical, can greatly assist in ensuring the best materials and practices are used for your project, while also saving you money as the more economical solution.

SITE Geotechnical offers pavement rehabilitation services by conducting Reports & Recommendations.

Do you need geotechnical engineering in Melbourne? Reach out to the team at SITE Geotechnical, your trusted leaders for pavement design in Melbourne since 2005. We have a combined 80 years of experience in our field, which is showcased through our thorough and wide range of professional services designed to maximise efficiency while providing you with savings in cost.

Get in touch with our team by calling 1300 557 260 or filling out an enquiry form online. Our geotechnical engineers are excited to assist you with your next pavement project! For more information, check out our blog on the Benefits Of Conducting A Geotechnical Survey Before Construction and our pavement inspection case study.

A successful building project starts with the soil foundation. Learn why conducting a geotechnical survey before construction is crucial for stability and efficiency.

Have you noticed cracks in the walls or ceiling of a building? Are your doors or windows no longer closing easily? Small cracks are no cause for alarm, but larger ones are the signs of a distressed building, and the underlying cause needs to be looked into straight away. A distressed building will need more […]

Having the right or wrong pavement design can make millions of dollars difference in a project. That’s why it’s so important to do your pavement design correctly the first time around, and this includes choosing the right team of pavement engineers for the job. Pavement design is about more than footpaths–it actually influences all kinds […]

Geotechnical site investigations often involve the use of a drilling rig in a wide and open space, but what if the areas you are trying to work on have size or access constraints? In these circumstances, you’ll need access to geotechnical drilling technologies that can work for both small and large-scale infrastructure projects. This is […]

At Site Geotechnical, we understand that wetlands play an essential role in land development projects across the country. While most of our clients are already familiar with their environmental benefits, such as flood mitigation and water quality improvement, our focus is on the geotechnical considerations that can help wetlands perform reliably and sustainably. Let’s discover […]

In the midst of planning a construction project? Whether you’re building a road, a bridge, a commerce centre, or a dam, the earth you’ll be working with can have a profound impact on the success of your project. Geotechnical services consist of many different types of studies and tests on a particular site that delve […]

When you think of recycling, your mind might immediately go to paper or cans, but did you know recycled construction and waste materials play a strong part in pavement design in Melbourne as well? Pavement is everywhere, from our sidewalks and personal driveways to roads, construction platforms and rail trails. Expanding cities are constantly creating […]

For two decades, SITE Geotechnical Pty Ltd has been at the forefront of geotechnical engineering, providing expert investigations and recommendations that ensure strong, lasting foundations for infrastructure and development projects. Our journey from a small consulting firm to a leading geotechnical service provider in Victoria has been defined by innovation, expertise, and an unwavering commitment […]

In the world of infrastructure, maintaining and upgrading pavements is a constant challenge. Victorian roads endure heavy traffic, harsh weather, and can simply wear down over time, often leading to deterioration that demands action. Historically, a full reconstruction—ripping out old pavement and starting fresh—has been the go-to solution. But there’s a smarter, more sustainable alternative: […]