At SITE Geotechnical, we have spent over twenty years helping to shape Victoria’s infrastructure. From residential estates to arterial roads, we have seen the industry shift toward designs that focus not only on performance but also on environmental responsibility, cost efficiency and long-term resilience.

Today, sustainable pavement construction is no longer a niche idea. It is becoming a core part of how councils, developers and contractors deliver value to their communities.

In one of our recent LinkedIn posts, we highlighted a project that demonstrates how sustainable pavement ideas can be applied in real settings. Foam bitumen stabilisation, in particular, is proving to be a powerful tool for pavement upgrades and rehabilitation.

In this blog, we explore why sustainable design matters, how modern stabilisation techniques are changing the industry, and how collaboration across councils, contractors and geotechnical specialists is producing smarter and more durable roads.

Traditional pavement construction often relied on extensive excavation and replacement. When a road reached the end of its life, the usual response was to remove large sections of the existing pavement and import new layers of aggregate and asphalt.

While effective in certain contexts, this approach consumes significant amounts of natural resources and generates quite a bit of construction waste. It can also lead to prolonged disruption for road users.

Smarter road design focuses on re-use, resilience and long-term performance. The goal is to preserve and enhance the materials already in place wherever possible. When combined with an accurate geotechnical investigation and modern modelling tools, this approach can significantly reduce the environmental footprint of construction without compromising structural strength.

Sustainable pavement design in Melbourne offers several benefits, including:

These outcomes make sustainable design an essential consideration for major road authorities like Department of Transport and Planning (DTP), Regional Roads Victoria (RRV), Major Road Projects Victoria (MRPV), Major Transport Infrastructure Authority (MTIA), VicTrack, councils, and contractors looking at innovative alternatives that are practical to build and developers who want to maximise both environmental and financial value.

SITE Geotechnical offers geotechnical engineering, pavement investigation and pavement design services across Victoria. Since 2005, we have completed more than 10,000 projects, giving us extensive experience across a wide range of ground conditions, pavement types and performance requirements.

Our work focuses on understanding the ground first, and we know that a thorough geotechnical investigation is the foundation of effective design. Typical investigations include soil classification, density and moisture assessments, CBR testing, permeability testing, and evaluation of pavement layers through test pits and/or cores and/or boreholes. Understanding these conditions allows us to design pavements that are durable and appropriate for the site.

Our pavement services include:

By combining advanced modelling tools with rigorous field and laboratory assessment, we can recommend solutions that prioritise re-use, performance and sustainability. Foam bitumen stabilisation is one of the techniques that align particularly well with these objectives.

Foam bitumen stabilisation (FBS) has emerged as one of the most effective methods for rehabilitating roads while significantly reducing environmental impact. The process involves injecting air and water into hot bitumen to create a foam that expands in volume and reduces viscosity. This allows the bitumen to coat and bind granular materials more effectively.

The foam is then mixed with existing pavement materials, often with a small proportion of cement or lime, to produce a strong, flexible and moisture-resistant base layer.

The benefits of FBS include:

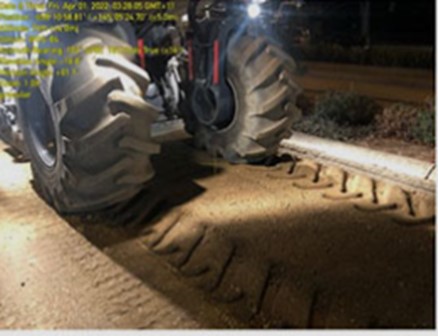

A recent project featured on our LinkedIn page illustrates how sustainable pavement solutions can deliver real outcomes for councils and communities. SITE Geotechnical was engaged by Brimbank City Council to support the rehabilitation of Theodore Street in St Albans, a local road requiring structural improvement and an upgrade in durability.

After completing geotechnical investigations and pavement assessments, we recommended foam bitumen stabilisation along with other rehabilitation and reconstruction options for comparison. In the end, the client chose foam bitumen stabilisation as the most effective option. The existing pavement materials had sufficient potential to be reused and strengthened, making FBS an ideal option for extending the life of the road while reducing construction waste and lessening the need for newly imported materials.

The rehabilitation was carried out by Roadstone Recycling, one of Victoria’s leading specialists in pavement recycling. Their team delivered the works efficiently with smooth production, accurate stabilisation, and quality compaction. Their operational capability was an essential part of the project’s success.

Theodore Street now benefits from a durable, flexible and sustainable pavement structure that is designed to serve the local community for many years. The project demonstrates how strong collaboration between Brimbank City Council, Roadstone Recycling and SITE Geotechnical can lead to high-quality infrastructure outcomes that also advance important sustainability objectives.

This project is a clear example of how councils can modernise their local road networks through stabilisation and recycling techniques that are both environmentally responsible and financially prudent.

Sustainable pavement design requires more than selecting eco-friendly binders or recycling existing pavement layers. It relies on a holistic approach that considers the entire lifecycle of the pavement.

At SITE Geotechnical, this approach involves:

As infrastructure demands increase and environmental expectations continue to grow, sustainable pavement design will remain essential. Major road authorities, Contractors, Councils and developers are seeking solutions that deliver long-term value, minimise waste, are easy to build and reduce environmental impact. Foam bitumen stabilisation, in-situ recycling and informed design will continue to play a major role in meeting these goals.

SITE Geotechnical remains committed to working with local government, contractors and developers to deliver pavements that are durable, cost-effective and environmentally responsible. Our project on Theodore Street in St Albans is just one example of how collaboration and modern engineering can produce meaningful and future-focused results.

By combining rigorous pavement investigations, thoughtful design and innovative construction techniques, we can continue to build smarter roads that meet the needs of communities today while protecting our environment for tomorrow.

Contact us for any type of geotechnical engineering in Melbourne you need on 1300 557 260.

A successful building project starts with the soil foundation. Learn why conducting a geotechnical survey before construction is crucial for stability and efficiency.

You may not think much about the pavement beneath your feet, but a great deal of planning and preparation goes into the design, creation and laying of pavement. Pavement design in particular needs a lot of careful thought, as it is used in critical infrastructure projects such as the building of major highways, warehouses, large […]

Have you noticed cracks in the walls or ceiling of a building? Are your doors or windows no longer closing easily? Small cracks are no cause for alarm, but larger ones are the signs of a distressed building, and the underlying cause needs to be looked into straight away. A distressed building will need more […]

Having the right or wrong pavement design can make millions of dollars difference in a project. That’s why it’s so important to do your pavement design correctly the first time around, and this includes choosing the right team of pavement engineers for the job. Pavement design is about more than footpaths–it actually influences all kinds […]

Geotechnical site investigations often involve the use of a drilling rig in a wide and open space, but what if the areas you are trying to work on have size or access constraints? In these circumstances, you’ll need access to geotechnical drilling technologies that can work for both small and large-scale infrastructure projects. This is […]

At Site Geotechnical, we understand that wetlands play an essential role in land development projects across the country. While most of our clients are already familiar with their environmental benefits, such as flood mitigation and water quality improvement, our focus is on the geotechnical considerations that can help wetlands perform reliably and sustainably. Let’s discover […]

In the midst of planning a construction project? Whether you’re building a road, a bridge, a commerce centre, or a dam, the earth you’ll be working with can have a profound impact on the success of your project. Geotechnical services consist of many different types of studies and tests on a particular site that delve […]

When you think of recycling, your mind might immediately go to paper or cans, but did you know recycled construction and waste materials play a strong part in pavement design in Melbourne as well? Pavement is everywhere, from our sidewalks and personal driveways to roads, construction platforms and rail trails. Expanding cities are constantly creating […]

For two decades, SITE Geotechnical Pty Ltd has been at the forefront of geotechnical engineering, providing expert investigations and recommendations that ensure strong, lasting foundations for infrastructure and development projects. Our journey from a small consulting firm to a leading geotechnical service provider in Victoria has been defined by innovation, expertise, and an unwavering commitment […]

In the world of infrastructure, maintaining and upgrading pavements is a constant challenge. Victorian roads endure heavy traffic, harsh weather, and can simply wear down over time, often leading to deterioration that demands action. Historically, a full reconstruction—ripping out old pavement and starting fresh—has been the go-to solution. But there’s a smarter, more sustainable alternative: […]