Building any sort of structure in Melbourne means you need to have a plan in place to deal with its soil. At Site Geotechnical, we can investigate and look at what is needed to provide your project with a solid foundation. Throughout Victoria, clay soils can and do wreak havoc on structures, such as pavements, that are not designed appropriately, and this is where we come in.

At SITE Geotechnical, our pavement design services consider the reactivity of the soils you’re trying to build on. Creating roads, pathways, platforms and slabs you can rely on to stay strong and perform as expected is our specialty.

Here is what you need to know about reactive clay soils, and how we design and upgrade existing roads to cater for reactivity within the soil.

Reactive clay soils can cause a lot of headaches for road builders, contractors, engineers and users, so let’s dive into exactly what they are, and how they affect pavements and buildings across Melbourne.

‘Reactive clay soils’ are known to shrink and swell with changes in moisture content, and are sometimes referred to as ‘shrink-swell clay’ or ‘expansive soils’ due to the way they react to water, or a lack of it. These clay soils will expand when they absorb water, becoming larger and increasing in volume with enough force to lift buildings and roads built on top of them up. Then, when water or moisture is scarce or the soil dries, it will shrink and contract, pulling the surrounding soil in and any structures built on top down.

Everything built on reactive clay soil will need to keep these potential movements in mind, so precautions can be taken to limit the damage it can cause.

If you don’t take reactive soil into account, you’ll find that any pavement will suffer from defects associated with shrink-swell defects. Here are a few examples of what can happen to pavement that is built on reactive soil without preparation.

Ideally, roads, pathways, and driveways (generally referred to as pavements) would maintain the same shape as when they were constructed. Rising and falling in sections, and substantial cracks, can increase the level of maintenance, reduce life, require upgrading or ruin rideability.

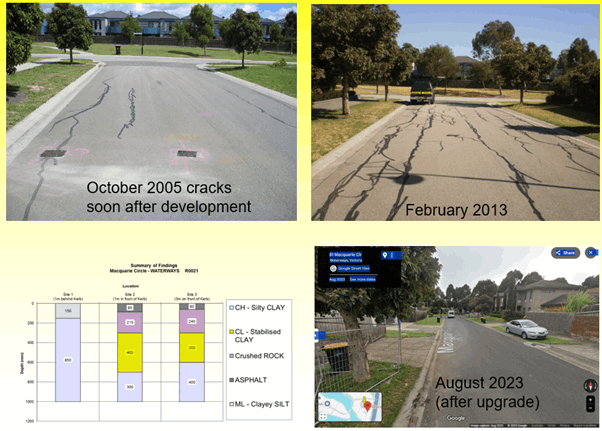

The following example illustrates what can happen when there are differential or abnormal moisture conditions within reactive soils within roads. The following defects, including Near-Parallel Longitudinal Cracks, are usually related to volume change of expansive clay subgrade, cyclical weakening of the pavement edge, differential settlement between cut and fill, or reflection of cracks in underlying cemented sub-base. In this case, the defects were found to be related to differential moisture conditions across the pavement width.

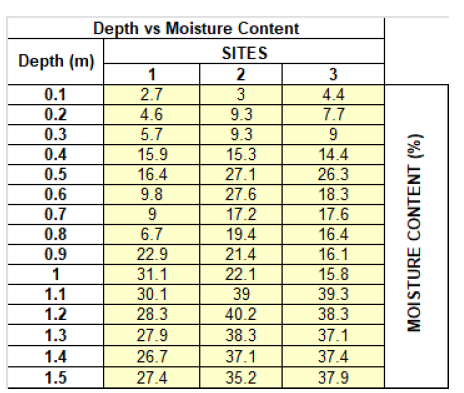

The following tables and graphs compare the moisture contents of the samples taken from beneath the existing pavement. They show a clear variation in moisture contents, with the test pits undertaken along the outer edge of the pavement generally having a lower (drier) moisture content than those undertaken beneath the pavement.

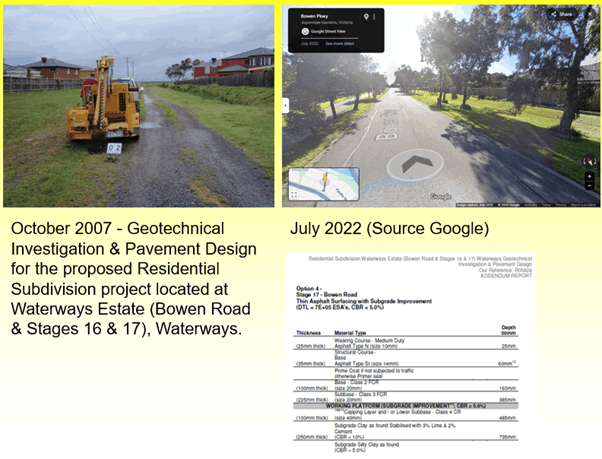

When designing subdivisional roads in areas with expansive soils, pavement design plays a critical role in long-term performance. A clear example can be seen in two roads constructed within the same geological area and subdivision, but with starkly different outcomes due to their design approaches.

One road, designed without accounting for the expansive nature of the subgrade, exhibited significant cracking soon after opening and distress that required a new surfacing prior to its 20 year design life. This design, prepared by external engineers, failed to address the soil’s potential for volume changes due to moisture fluctuations, leading to poor performance.

In contrast, another road in the same area, designed by SITE Geotechnical engineers, incorporated a capping layer to mitigate the effects of expansive soils. This layer provided a stable base, reducing the impact of subgrade movement and ensuring a durable pavement surface. The difference is that the defects were much greater when the road did not incorporate a capping layer and has not been resurfaced or significantly upgraded. This road would have performed even better with a shoulder and less trees, however that all comes down to conflicting aims and cost. The illustrations and examples highlight the importance of tailoring pavement design to site-specific geotechnical conditions.

By prioritising geotechnical input and incorporating measures like capping layers, engineers can significantly enhance the longevity and performance of roads built on expansive subgrades.

No matter the issues you’re having with your pavement, one of our many pavement design services will be able to help you.

Reactive soils, which expand and contract with moisture changes, can wreak havoc on road pavements. These soils, often rich in clays like montmorillonite, create a host of issues that compromise road safety and longevity.

Below, we highlight some of the most obvious pavement defects caused by reactive soils and why they matter for drivers and engineers alike in Victoria.

Reactive soils are notorious for causing cracks in road surfaces due to their shrinking and swelling behaviour. Here are the main types you’ll spot:

Cracks not only make for a bumpy ride but also allow water to seep into, worsening the problem over time.

Ever hit an unexpected bump on a smooth road? That’s likely heaving, where swelling soils push the pavement upward after heavy rain. This creates uneven surfaces, waves, or pumps that can jolt vehicles and reduce driving comfort. In extreme cases, it’s a safety hazard, especially for high-speed roads.

Rutting shows up as depressions or grooves in the wheel paths, often caused by reactive soils softening when wet or compressing unevenly under traffic. These ruts collect water, increasing skid risks and making roads harder to navigate, particularly in wet conditions.

Along the edges of roads, where support is weaker, reactive soils can cause the pavement to crack and break away. As the soil shrinks or swells, it destabilises the road’s shoulder, leading to jagged cracks that erode the pavement’s integrity and create uneven edges.

Potholes are the bane of every driver’s existence, and reactive soils are often to blame. Severe soil movement can create voids beneath the pavement, causing localised collapse. After prolonged wet conditions, these voids turn into potholes, jarring vehicles and posing significant repair challenges.

These defects, driven by reactive soils, aren’t just cosmetic–they impact road safety, vehicle maintenance, and infrastructure costs. Areas with highly reactive clay soils are particularly prone, and poor drainage or inadequate pavement design can make things worse.

Regular monitoring, proper drainage systems, and robust foundation designs are key to minimising these issues. By understanding and addressing the effects of reactive soils, engineers can build more durable roads, and drivers can enjoy smoother, safer journeys across Victoria–and Australia, for that matter.

Victoria’s roads face unique challenges from reactive soils, particularly in regions like Melbourne’s western suburbs, Geelong, and the volcanic plains, where expansive clays wreak havoc on pavements. These soils, which swell and shrink with moisture changes, cause defects like crocodile cracking, heaving, rutting, edge cracking, and potholes, driving up maintenance costs and compromising safety.

While these issues resonate across Australia, Victoria’s wet climate and clay-rich soils amplify the problem. We will now explore how reactive soils impact Victorian roads, how to classify their expansiveness using industry-standard tools, and best practices for designing durable pavements, drawing on the Austroads Guide to Pavement Technology Part 2: Pavement Structural Design (2024).

To build resilient roads on Victoria’s reactive soils, engineers must quantify soil expansiveness. The Austroads Guide to Pavement Technology Part 2: Pavement Structural Design (2024) offers Table 5.2: Guide to Classification of Expansive Soils, a key tool for assessing soil reactivity. It uses three metrics:

The classifications are:

The swell test, preferred for its accuracy, mimics Victoria’s wet seasons, helping predict soil behaviour. Using Table 5.2, engineers can design pavements with thicker layers or stabilisation to combat defects like crocodile cracking or heaving.

Effective pavement design on Victoria’s reactive soils starts with thorough subgrade evaluation, as the subgrade’s support is critical for pavement thickness, composition, and performance. The Austroads Guide to Pavement Technology Part 2 (2024) emphasises measuring subgrade support via California Bearing Ratio (CBR) or elastic parameters (vertical/horizontal modulus, Poisson’s ratio), influenced by soil type, density, and moisture.

Engineers assign a design CBR for each uniform subgrade unit, defined by Victoria’s varied topography, drainage, and clay-rich soils. Key considerations include subgrade variability, performance risks, earthworks construction, compaction moisture content, in-service moisture changes (critical in Victoria’s wet climate), pavement cross-section, drainage, and weak layers below the subgrade.

Expansive soils, prevalent in areas like western parts of Melbourne where basaltic (volcanic) soils known for their high reactivity, cause pavement deformation, classified using Table 5.2. Strategies like compacting at equilibrium moisture content, adding low-permeability capping layers, and using sealed shoulders result in stable, durable pavements that reduce costly repairs on Victorian roads.

To counter reactive soils, the Austroads Guide and VicRoads standards recommend:

These measures, guided by Table 5.2, help Victorian engineers design resilient roads.

Victoria’s clay-rich soils, combined with its wet winters and variable climate, make reactive soils a major challenge for road networks, from Melbourne’s urban arterials to rural highways and residential roads. By using Table 5.2 and Austroads’ subgrade evaluation guidelines, alongside VicRoads’ local expertise, engineers can predict soil behaviour and mitigate defects. Cross-referencing with AS 2870-2011 Table 2.1 (classifying sites as A, S, M, H1, H2, E, P) and site-specific testing (per AS 1289) can be used for a robust approach. The result is smoother, safer roads that reduce maintenance costs and enhance driver safety across Victoria.

What’s Next? Victorian engineers and road authorities should prioritize geotechnical testing, classify soil reactivity, and adopt Austroads’ strategies to build roads that stand up to the state’s challenging soils. Victoria’s commuters deserve durable, reliable infrastructure.

At SITE Geotechnical, we often perform distressed building investigations and distressed pavement investigations to determine the cause of the cracking and defects you’ll so often see by moving clay soils. We often find that unusual moisture levels and subsequent soil movements can be caused by poor surface drainage conditions, incorrectly created and installed stormwater systems, a proximity to water-seeking trees and plants, and leaking pipes underground.

Our pavement rehabilitation services are known for strengthening existing pavements for the future, increasing their longevity and saving projects a lot of money on repairs down the track.

Do you need pavement upgrades and rehabilitation, or just a pavement investigation to find out what’s what? We are the team to trust with any geotechnical services in Melton, Tarneit, or Gippsland that you might need.

If you’re concerned about building pavement on potentially reactive clay soil, it’s time to reach out to our geotechnical engineering experts in Melbourne.

SITE Geotechnical has been providing our clients with the best geotechnical and pavement design services since 2005, and we pride ourselves on offering you clear and fair quotes, detailed reports and everything else you need for your project to succeed.

You can look to us for a range of design services for a variety of pavement types, including:

We can also help rehabilitate your pavement and make it future-proof using recycled materials.

Get in touch using our online message form for a prompt response to your query. Otherwise, call us on 1300 557 260 to speak directly with a member of our team. As members of Engineers Australia and the Australian Geomechanics Society, you can trust us to help your project succeed from the ground up!

A successful building project starts with the soil foundation. Learn why conducting a geotechnical survey before construction is crucial for stability and efficiency.

You may not think much about the pavement beneath your feet, but a great deal of planning and preparation goes into the design, creation and laying of pavement. Pavement design in particular needs a lot of careful thought, as it is used in critical infrastructure projects such as the building of major highways, warehouses, large […]

Have you noticed cracks in the walls or ceiling of a building? Are your doors or windows no longer closing easily? Small cracks are no cause for alarm, but larger ones are the signs of a distressed building, and the underlying cause needs to be looked into straight away. A distressed building will need more […]

Having the right or wrong pavement design can make millions of dollars difference in a project. That’s why it’s so important to do your pavement design correctly the first time around, and this includes choosing the right team of pavement engineers for the job. Pavement design is about more than footpaths–it actually influences all kinds […]

Geotechnical site investigations often involve the use of a drilling rig in a wide and open space, but what if the areas you are trying to work on have size or access constraints? In these circumstances, you’ll need access to geotechnical drilling technologies that can work for both small and large-scale infrastructure projects. This is […]

At Site Geotechnical, we understand that wetlands play an essential role in land development projects across the country. While most of our clients are already familiar with their environmental benefits, such as flood mitigation and water quality improvement, our focus is on the geotechnical considerations that can help wetlands perform reliably and sustainably. Let’s discover […]

In the midst of planning a construction project? Whether you’re building a road, a bridge, a commerce centre, or a dam, the earth you’ll be working with can have a profound impact on the success of your project. Geotechnical services consist of many different types of studies and tests on a particular site that delve […]

When you think of recycling, your mind might immediately go to paper or cans, but did you know recycled construction and waste materials play a strong part in pavement design in Melbourne as well? Pavement is everywhere, from our sidewalks and personal driveways to roads, construction platforms and rail trails. Expanding cities are constantly creating […]

For two decades, SITE Geotechnical Pty Ltd has been at the forefront of geotechnical engineering, providing expert investigations and recommendations that ensure strong, lasting foundations for infrastructure and development projects. Our journey from a small consulting firm to a leading geotechnical service provider in Victoria has been defined by innovation, expertise, and an unwavering commitment […]

In the world of infrastructure, maintaining and upgrading pavements is a constant challenge. Victorian roads endure heavy traffic, harsh weather, and can simply wear down over time, often leading to deterioration that demands action. Historically, a full reconstruction—ripping out old pavement and starting fresh—has been the go-to solution. But there’s a smarter, more sustainable alternative: […]